Durable Stainless Steel Tubes for Modern Architectural Designs

Benefits of Durable Stainless Steel Tubes in Architecture

Corrosion Resistance for Longevity

The natural ability of stainless steel to resist rust and corrosion really adds years to how long architectural components last, which makes it a great choice for buildings in tough weather conditions. Studies show that these materials can stick around for 50 years or more in some pretty rough spots, cutting down on how often things need replacing. Safety becomes another big plus when we talk about corrosion resistance. Over time, buildings stay stronger and safer because their structural parts don't break down as quickly, something that matters a lot when people are living or working inside those spaces.

Structural Integrity Under High Stress

Stainless steel tubes built to last can handle serious weight and pressure, making them perfect for holding up important parts of buildings and structures like tall buildings and big bridges. These tubes have way better strength than regular steel actually about half again as strong which adds extra protection when things get tough on construction sites. We see this material used all over places where nothing can go wrong because it just keeps everything standing even when faced with really harsh situations.

Aesthetic Versatility for Modern Designs

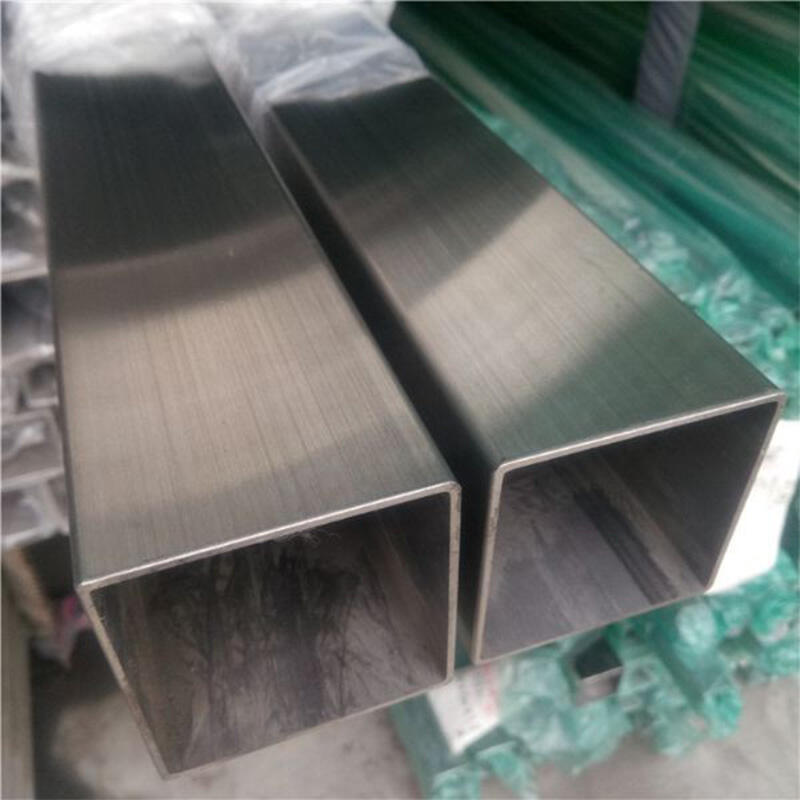

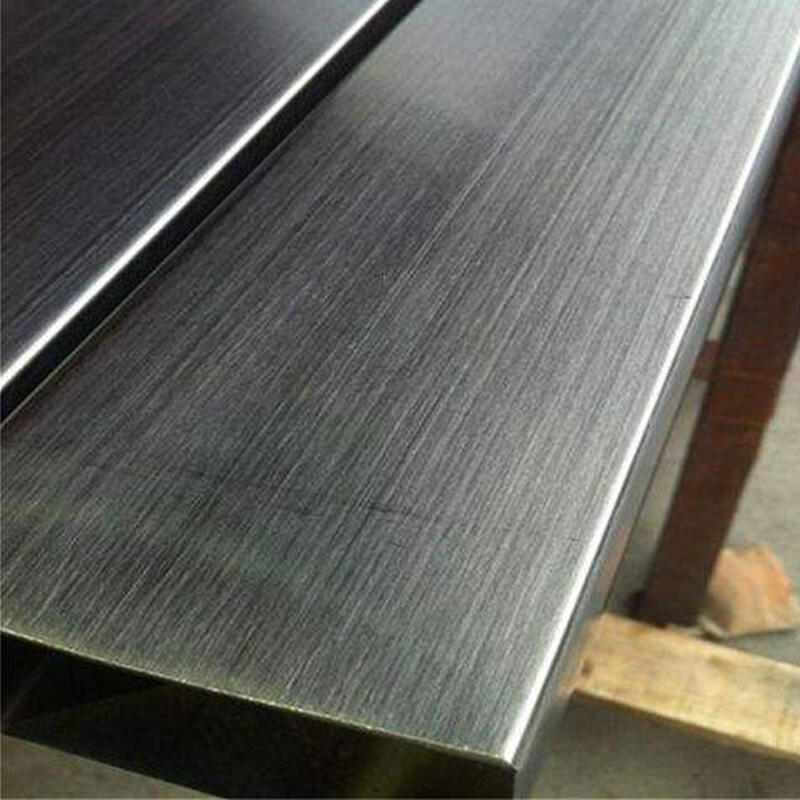

Architects love working with stainless steel tubes because they come in so many different looks. The material can take on finishes ranging from shiny polished surfaces to subtle brushed textures or even dull matte appearances. What's really cool is how these tubes blend right into almost any building style without standing out too much. Stainless steel actually reflects light pretty well, which means buildings using this material tend to feel brighter inside during daylight hours. Take the new downtown library for instance it uses stainless steel panels throughout and the whole space just glows when sunlight hits them. For designers looking to create spaces that look good while still serving their purpose, stainless steel remains one of the top picks in today's architecture scene where bold yet elegant designs are all the rage.

Applications of Stainless Steel Tubes in Modern Construction

Structural Frameworks and Support Systems

Stainless steel tubes play a critical role in supporting modern buildings and structures across the construction industry. Their combination of strength and relatively low weight makes them perfect for everything from towering skyscrapers to intricate bridge designs. When builders incorporate these tubes into their projects, they actually end up creating lighter structures without sacrificing stability or durability. Architects love working with stainless steel because it allows them to push design boundaries while keeping safety intact. Real world applications show that buildings with stainless steel frames often require less total material than traditional options. This reduction translates directly into cost savings and better environmental performance since there's simply less resource consumption involved in the construction process.

Decorative Elements in Façades and Interiors

Stainless steel tubes have become pretty common in modern architecture for both exterior and interior design work. On the outside of buildings, these metal tubes create interesting textures and patterns that really stand out against walls and windows, making facades look much more attractive than plain surfaces would. Inside commercial spaces and homes alike, architects frequently incorporate them into handrails, light fixtures, and structural supports. The material works well because it's strong yet lightweight, letting designers experiment with shapes and configurations that wouldn't be possible with other materials. Many contemporary offices and restaurants now feature custom stainless steel installations that serve practical purposes while also creating striking visual statements. Some designers even talk about how the reflective surface can play with natural light in ways that enhance the overall atmosphere of a space.

HVAC and Fluid Transport Systems

Stainless steel tubes play a vital role in HVAC systems because they can keep temperatures stable while standing up to corrosion. The fact that these tubes last so long means they become a trusted part of any plumbing setup. Many industries rely on them for moving all sorts of fluids through their systems since they handle really high pressures without breaking down. We're talking about pressure levels that would make regular pipes fail within weeks. That's why we see them everywhere from massive factories pumping chemicals around to small homes where hot water needs to reach every faucet reliably. The whole point is fewer breakdowns and less need for constant repairs, which saves money in the long run even if the initial cost seems higher.

Stainless steel tubes not only support structural integrity but also elevate aesthetic designs and offer operational reliability in transport systems. Their multifaceted use in modern construction showcases their indispensable role in achieving long-lasting durability, energy efficiency, and creative design solutions in architecture and engineering.

Material Grades: 201 vs. 304 vs. 316L Stainless Steel

201 Stainless Steel: Cost-Effective Durability

201 stainless steel strikes a nice middle ground between being easy to work with and not breaking the bank, which explains why so many builders turn to it for everyday construction jobs. The material holds up pretty well against rust too, at least in places that aren't super corrosive environments. This means buildings last longer without having to spend extra money on maintenance or replacements. When budget constraints matter most but we still need something reliable enough to hold everything together, 201 stainless makes sense for lots of different projects. We see this grade getting used a lot in situations where structures need to be strong relative to their weight, like certain types of machinery components or architectural features that don't face constant weather exposure.

316L: Premium Corrosion Resistance for Harsh Environments

When it comes to resisting corrosion, 316L stainless steel stands head and shoulders above most alternatives, which is why it works so well in tough spots like saltwater environments or chemical plants where other materials would quickly fail. What makes this particular grade special? Well, it keeps performing strong even when exposed to blistering heat or subjected to rough treatment day after day. The secret ingredient here is molybdenum, which gives the metal extra protection against those pesky pits and localized rust problems that plague regular 304 stainless steel in really harsh situations. Manufacturing sectors that need equipment they can trust in extreme conditions find themselves turning to 316L again and again because they know their tanks, pipes, and structural parts won't degrade prematurely or let them down during critical operations.

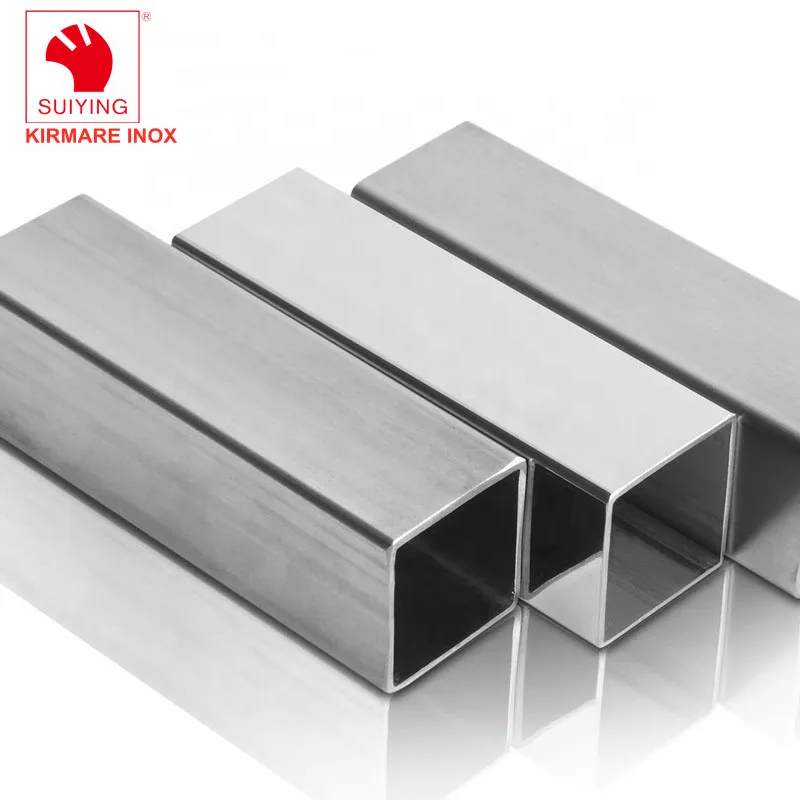

Top Stainless Steel Tube Products for Architectural Use

201 Stainless Steel Square Decorative Square Pipes

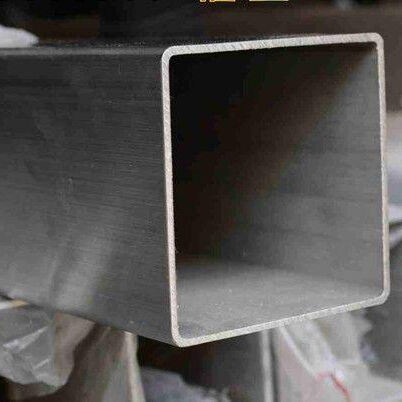

Stainless steel square decorative pipes made from grade 201 material have become a favorite among architects for both looks and strength. Many contemporary buildings feature these pipes because the clean lines and smooth surface really stand out in modern designs. The market offers all sorts of sizes and surface treatments too. Some designers prefer brushed finishes while others go for polished ones depending on what they want to achieve visually. Because they come in so many different specs, it's pretty easy to find something that matches almost any project requirements. This flexibility makes them work well whether installed as accent pieces or as functional elements within the overall structure.

201 Mirror Polished Stainless Steel Square Tubing

Stainless steel square tubing with mirror polish gives architectural projects that extra touch of luxury, bouncing light around and making spaces look really clean. What's great about this finish is that it looks fancy but stays looking good too since it resists those annoying finger marks and smudges that ruin appearances after a while. Because of these properties, architects often choose this material for decorative purposes inside buildings as well as outside structures where maintaining an elegant look matters a lot.

Hot-sale Stainless Steel Square Tubing 201

Stainless Steel Square Tubing 201 has become something of a favorite among builders and designers thanks to its sleek appearance and solid construction. Works great for everything from home renovations to big commercial builds. What makes this particular type stand out? Well, it tends to follow current design trends pretty closely, so architects keep an eye on how it performs in different applications. And let's not forget about pricing when dealing with bigger projects. Most suppliers will throw in discounts for bulk orders, which really adds up when contractors need hundreds of feet for structural work or decorative elements across multiple sites.

Hot-sale Stainless Steel Rectangular Pipes Specifications 201

Hot-sale Stainless Steel Rectangular Pipes Specifications 201 are versatile, extensively utilized for both structural and decorative applications. They allow for broad customization due to varied specifications, accommodating unique architectural designs. These products typically adhere to strict quality standards, ensuring both aesthetic and structural integrity in architectural undertakings.

316L Stainless Steel Decorative Rectangular Pipes

The 316L Stainless Steel Decorative Rectangular Pipes really stand out in upscale architecture, particularly when dealing with areas that tend to corrode over time. What makes these pipes special is how they manage to combine practicality with a touch of class, which is why architects often specify them for building exteriors as well as interior spaces. The specs on these pipes have been designed to satisfy tough industry requirements and building regulations. This means they perform reliably while still looking great in construction projects where looks matter just as much as lasting power. Many designers appreciate this balance between beauty and strength when specifying materials for their next big project.

Selecting the Right Stainless Steel Tube for Your Project

Matching Material to Environmental Demands

The environment plays a big role when choosing the right stainless steel grade for any given application. Various grades come with different strengths regarding rust protection and overall toughness, so picking the correct material depends heavily on what kind of conditions it will face day after day. Take coastal construction work as an example saltwater and sea spray can really eat away at standard materials over time, which means going for a premium stainless option becomes necessary. Getting input from structural experts helps make sure all these material decisions actually fit what the project needs, balancing long term performance against initial costs without compromising safety or effectiveness.

Customization Options for Unique Designs

The manufacturing world has really stepped up game when it comes to customizing stainless steel tubes, giving architects plenty of creative freedom to make their mark on buildings. Designers can now pick exactly what size, finish, and grade they want, so these metal tubes work both looks-wise and functionally for whatever the job needs. When projects get this level of customization, the whole space just feels better put together. The tubes blend right in without looking out of place. Many architects choose customized solutions because those little details matter a lot. Take commercial buildings with sleek stainless steel square tubes forming part of their exterior skin, or office spaces where curved tubes form decorative elements inside. These aren't just pretty additions they actually support structural integrity while adding that signature touch that makes each building stand apart from others.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

LT

LT

SR

SR

SL

SL

UK

UK

TH

TH

TR

TR

FA

FA

AF

AF

GA

GA

IS

IS

MK

MK

AZ

AZ

BN

BN

LO

LO

LA

LA

MN

MN

MY

MY

KK

KK

KY

KY