KIRMARE က အင်ဂျင်နီယာရေး၊ အိုတေားမိုဘိုင်း နှင့် ဆောက်လုပ်ရေးလုပ်ငန်းများ၏ ရှုံးလှုပ်ရှားသော တောင်းဆိုချက်များကို ကိုက်ညီသော စတင်လေးခြောက်ဆိုင်ရာဖြေရှင်းချက်များကို ပေးပါသည်။ ပြင်ပလုပ်ဆောင်ရာ အောက်ရှိ အရွယ်အစားများနှင့် ပြုလုပ်ရေးများဖြင့် ကျွန်ုပ်တို့၏ စတင်လေးခြောက်ဆိုင်ရာလေးများသည် အသံ့အကြောင်းနှင့် ကားခြားမှုကို အကောင်အထည်ဖော်ထားသည်။ KIRMARE ၏ အရွယ်အစားနှင့် ကူးသန်းမှုဆိုင်ရာ ဝါဒီများကို ကိုက်ညီသော ကုမ္ပဏီများအတွက် ကုန်ပျော်နှင့် ထုတ်လုပ်ရေးလုပ်ငန်းများကို လျှော့ချပါသည်။

တစ်ကြိမ်တိုင်း Kirmare stainless steel bar အဲဒီကိရိယာဟာ အောလ်ထရွန်စ်စမ်းသပ်ခြင်း၊ ဓာတုဗေဒဆုံးဖြတ်ခြင်းနှင့် macro-etch စစ်ဆေးခြင်းတို့ကို ဖြည့်ဆည်းပြီး ပါဝင်မှု သို့မဟုတ် ပျက်ကွက်များရှိမရှိ စစ်ဆေးသည်။ ကျွန်တော်တို့ရဲ့ လှုပ်ရှားမှုဖြင့် အလုပ်လုပ်တဲ့ အစီရင်ခံစနစ်တွေဟာ ကြော်ငြာမှုနဲ့ ပြင်ပေါ်ပုံအရ ရောင်းသူများရဲ့ အမှန်တော်ချက်တွေနဲ့ ကိုက်ညီမှုကို ချိတ်ဆက်ပေးပါတယ်။ B2B ပါတညီများအတွက် ဒီလို ပြင်ပြီးသော လုပ်ငန်းစဉ်ဟာ အမှန်တော်မရှိ ပစ္စည်းများနဲ့ စစ်ဆေးခြင်းရဲ့ အချိန်နှင့် ကျွန်းစိတ်ကို လျော့နည်းစေပါတယ်။

Kirmare ပေးရန်တွင် အထူးသဖြင့် ကောင်းမွန်စွာ ဆိုင်ရာ သံမဏိ သံမဏိ သံချပ် အุตสาหกรรมဆိုင်ရာ လိုအပ်ချက်များအတွက် ထပ်မံဖွဲ့စည်းထားသည်။ အချင်းအမှတ်၊ အရှည်၊ အလီဂျီး (304၊ 316၊ 410) သို့မဟုတ် မျက်နှာပြင်ခြင်း (ပိုလီရှ်၊ pickled)—ကျွန်ုပ်တို့ရဲ့ အသင်းအဖွဲ့က 15 လုပ်ငန်းရက်အတွင်း တိကျစွာ ယာဉ်ပြုလုပ်ထားသော ဘားများကို ပေးပို့ပါသည်။ B2B ဝင်ရိုင်များအတွက် ထပ်မံခြင်းက ဒုံးပစ္စည်းလျှော့ချမှုကို လျှော့ချပြီး ထုတ်လုပ်မှုအချိန်ကို အမြဲတမ်းဖြင့် ပိုမိုလျှော့ချပါသည်။ Kirmare ၏ အင်ဂျင်နီယာရှင်များ၏ ပညာရှင်များကို အသုံးပြု၍ သင့် blueprint များနှင့် အညီအညွတ်ဖြစ်သော ဘားများကို source လုပ်ပါ။

လေယာဉ်အပိုင်းပိုင်းများနှင့် ကာဗီးအင်ဂျင်အပိုင်းပိုင်းများတွင် Kirmare ကိရိယာများသည် အာရုံစတီလေးခြင်းပါသည့် ဘားများဖြစ်သည် အရှိန်မှန်မှန်ဆိုင်ရာ သဘောတူညီချက်များကို AMS 5643/QQ-S-763 စတာန်များဖြင့် ကိုင်တွယ်ပြီး fatigue resistance နှင့် high-temperature stability ကို ချိတ်ဆက်ပေးသည်။ Kirmare ရဲ့ lightweight နှင့် robust bars တွေဟာ critical systems မှာ fuel efficiency နှင့် safety ကို optimize လုပ်ပေးပါတယ်။ just-in-time deliveries နှင့် tailored certifications တွေနဲ့ သင့် supply chain ကို streamline လုပ်ဖို့ ကျွန်တော်တို့နဲ့ partner ဖြစ်ပါ။

KIRMARE က ရောင်းခတ်မှုများအောက်တွင် အလုပ်လုပ်ဆောင်နိုင်ရန် ဒီဇိုင်းထုတ်ထားသည့် ကြေးရောင် ဖိုင်အုပ်များကို ပေးဆောင်ပါသည်။ အားလုံးအတွင်း အားကစားမှု၊ ပံ့ပိုးမှုပြင်ဆင်မှုနှင့် အရွယ်အစားအတိုင်း မှန်ကန်မှုကို စုစုပေါင်းစစ်ဆေးသည့် ကြေးရောင် ဖိုင်အုပ်တစ်ခုချင်းကို ပြုလုပ်သည်။ မိုက်ဖာဖက်ရှိသူများဖြစ်စေ၊ အင်ဂျင်နီယာများဖြစ်စေ၊ KIRMARE ၏ ကြေးရောင် ဖိုင်အုပ်များသည် သင့်ရဲ့ အလုပ်လုပ်ဆောင်မှုစွမ်းရည်များကို ကိုက်ညီပေးပါသည်။ KIRMARE သည် B2B ဝန်ကြီးများအတွက် လုပ်ငန်းစဉ်ကို အကောင်းဆုံးဖြင့် ပိုမိုလုပ်ဆောင်ရန် ပုံမှန်အစီအစဉ်ဆောင်ရွက်မှုများကို ပံ့ပိုးပါသည်။

၂၀၀၄ ခုနှစ်တွင် ဖိုင်စတင် ကီမာရဲ စတေးainless Steel Material Co., Ltd. တည်ထောင်ခဲ့ပြီး အများသော ပုံစံများအဖြစ် rectangle, square, round, oval နှင့် slotted varieties တို့ကို ပါဝင်သော အရည်အချင်းမြင့် စတေးainless steel ဆယ်တိုင်များ ထုတ်လုပ်ခြင်းတွင် ပူးပေါင်းထားသည်။ သူတို့သည် စတေးainless steel sheets နှင့် fittings တို့ကိုလည်း ပိုမိုဖြန့်ဖြူးခဲ့သည်။ အগု ?>< ဆိုင်ရာ စနစ်များနှင့် angganer satisfaction တို့ကို ထောက်ခံပေးခြင်းဖြင့် သူတို့သည် တီဗူ, LRQA, ASTM နှင့် EU အတိုင်း အများကြီးသော သိပ္ပံအမှတ်တံဆိပ်များကို ရရှိခဲ့သည်။ ၁၅ နှစ်ကျော်အတွင်း သူတို့သည် Canton Fair အတိုင်း ကုန်သွယ်ရေး fair များတွင် အကြံပြုပါက အကောင်းဆုံး business relationships များကို အတွင်းရှိနှင့် ပြင်ပတွင် တည်ဆောက်ခဲ့ပြီး ရှေ့တွင်း clients တို့ကို long-term cooperation တွင် ပါဝင်ရောက်ယူခြင်းကို တောင်းဆိုထားသည်။

အားမြင်သော ဆေးချိုးခြင်း၊ ကားရောဂါကာကွယ်ရေးအရ အားလုံးရှိသည်။

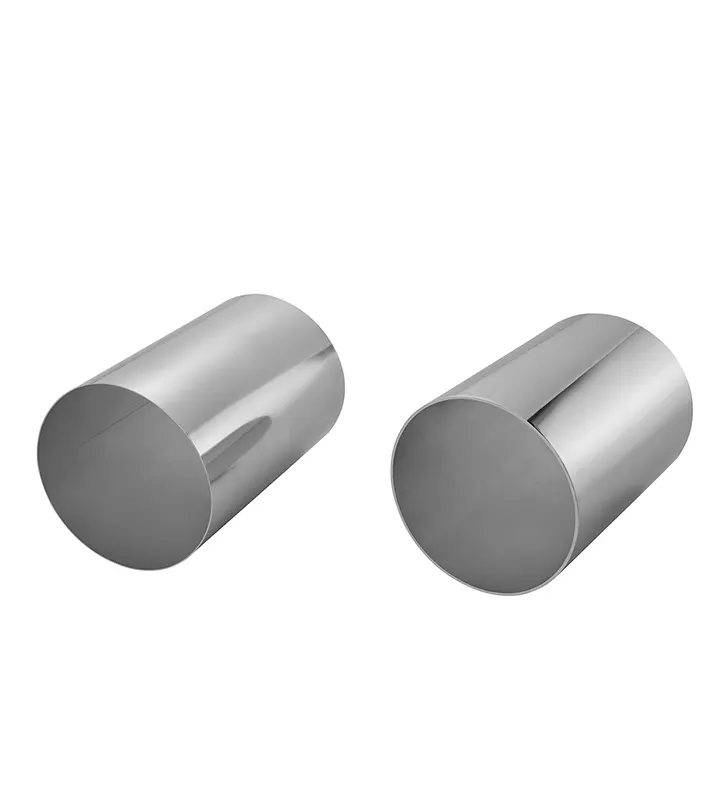

အလွန်ကောင်းသော မျက်နှာပြင်၊ ဒီဇိုင်းများအတွက် မျိုးမျိုးသော အရွယ်ရောက်မှုများ။

တူညီသော အရွယ်အစား မှန်ကန်မှု၊ ထိပ်တန်း ရုံးကြီးဆိုင်ရာ လုပ်ဆောင်မှု。

ပြင်းထန်သော အရောင်းအချိန် စ준များ၊ အဆုံးမရှိသော ผิวเผิน အရှိန်အသွေး။

ကျွန်ုပ်တို့သည် ကြေးရောင်များအတွက် ကိုက်ညီသော ကြေးရောင်အဆင့်များကို ပေးဆောင်ပြီး ကြေးရောင်များအတွက် ပိုမိုများသော ကြောက်ကြားမှုကို ကန့်သတ်နိုင်သည့် အင်ဂျင်နီယာရေးအဆင့်အတန်းများကို ပါဝင်သည်။

ဟုတ်ပါတယ်၊ KIRMARE သည် anggan အမှန်တကျ အရွယ်အစားများ၊ ပြင်ဆင်ခြင်းအတိုင်းအတာများနှင့် အလုပ်လုပ်ခြင်းနည်းလမ်းများကို anggan အမှတ်တံဆိပ်များအရ ထောက်ခံပါသည်။

ကျွန်ုပ်တို့၏ မီးကိုင်းမဟုတ်သော သံဃာဖြူကို တိုက်สร้างမှု၊ ကားများ၊ ကိရိယာများနှင့် ဖြဲရောင်ခြင်းအပိုင်းများတွင် ကျယ်ပြန့်သုံးလေ့ရှိပါသည်။

အားလုံးသော ထုတ်ကုန်များသည် ပတ်ဝန်းကျင်ဆိုင်ရာ ကမ္ဘာ့ ឧုံပြုမှုနှင့် အရေးပေါ်သော စီမံခန့်ခွဲမှုများအတိုင်း ထုတ်လုပ်နှင့် စစ်ဆေးခြင်းဖြင့် ပြုလုပ်ထားပါသည်။

ဟုတ်ပါတယ်၊ ကျွန်ုပ်တို့သည် အကြောင်းအရာ B2B anggan တို့နှင့် အရေအတွက်ကြီးမားသော အမှားများနှင့် ဆက်လက်ထုတ်လုပ်သော ပို့ဆောင်မှုပို့ဆောင်ခြင်းများတွင် အလုပ်လုပ်ပါသည်။

ကျွန်ုပ်တို့သည် ရှုံးလှုပ်ရှားသော စက်မှုများကို အသုံးပြုပြီး၊ ဒေသခံစစ်ဆေးမှုများကို လုပ်ဆောင်ပြီး၊ ထုတ်လုပ်မှုလုပ်ငန်းစဉ်အတွင်းတွင် ပုံမှန်အကိုးအကားများကို ထိန်းသိမ်းထားပါသည်။

Copyright © Copyright 2024@Foshan Kirmare Stainless Steel Material Co., Ltd.∙∙ ∙ပရိုင်ဗက်စီ